Across the UK manufacturing sector, production environments are changing faster than ever. Facilities are under pressure to reduce downtime, adapt layouts quickly and support evolving automation requirements. As a result, many engineers are reconsidering the long standing reliance on welded steel frames.

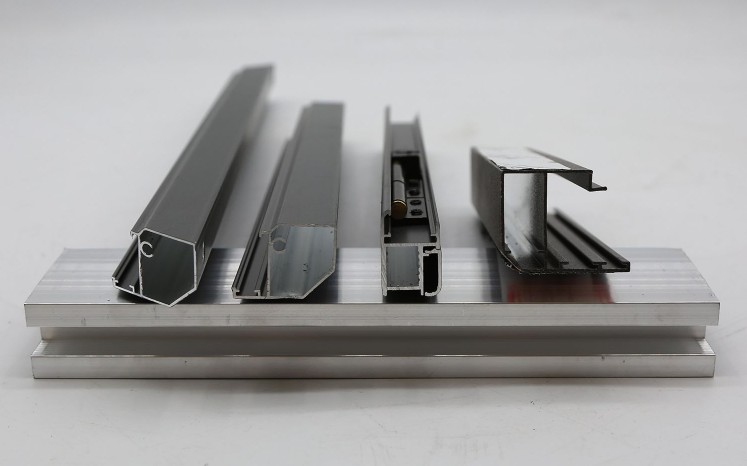

One solution increasingly being specified is modular aluminium profile systems, particularly T-slot framing, which offer a different approach to industrial structure design.

The Shift Away from Welded Steel Frames

Steel has traditionally been the default choice for machine frames and factory structures. However, its limitations become more apparent in modern manufacturing environments where flexibility matters as much as strength.

Common challenges with steel frames include:

- Long fabrication and installation times

- Permanent structures that are difficult to modify

- Higher labour costs due to welding and finishing

- Increased downtime during changes or repairs

These factors often conflict with lean manufacturing principles and continuous improvement strategies.

Faster Assembly, Less Disruption

One of the most immediate advantages of aluminium profile systems is speed. Unlike steel frames, aluminium structures are assembled using mechanical fasteners rather than welding.

This results in:

- Quicker on-site installation

- Minimal disruption to active production areas

- Easier dismantling or relocation

- Reduced reliance on specialist fabrication skills

For UK manufacturers operating live factory floors, this speed can significantly reduce production interruptions.

Designed for Change and Reconfiguration

Modern manufacturing layouts rarely stay the same for long. New machinery, revised workflows and automation upgrades often require structural changes.

Aluminium profile systems are inherently modular, allowing:

- Frames to be extended or reduced

- Components to be repositioned without cutting

- Existing profiles to be reused in new builds

This flexibility makes aluminium framing particularly suitable for automation cells, workstations and machine guarding that may need regular adjustment.

Strength Without Excess Weight

While steel remains necessary for very high load applications, aluminium profile systems offer a strong balance between rigidity and weight.

Key advantages include:

- High strength to weight ratio

- Easier manual handling during installation

- Lower structural load on floors and platforms

For many industrial applications, aluminium provides sufficient strength without the drawbacks of heavier steel constructions.

Long Term Durability and Lower Maintenance

Aluminium’s natural corrosion resistance makes it well suited to many UK industrial environments, including areas exposed to moisture, chemicals or temperature variation.

Unlike steel, aluminium profiles do not require painting or surface treatments to prevent rust, helping reduce:

- Ongoing maintenance requirements

- Long term appearance degradation

- Downtime linked to repairs or refinishing

Those researching modern framing solutions often begin by exploring available aluminium profile systems to compare specifications and configuration options.

Frequently Asked Questions

Are aluminium profile systems suitable for UK factories?

Yes. They are widely used across UK manufacturing for machine frames, guarding, conveyors and workstations.

Can aluminium profiles be modified after installation?

Yes. One of their main advantages is the ability to reconfigure structures without welding or permanent alterations.

Do aluminium frames meet safety requirements?

When correctly designed and assembled, aluminium profile systems can support compliance with UK machinery and workplace safety standards.

Is steel still necessary in some cases?

Yes. Extremely heavy load or high impact applications may still require steel, but many standard structures no longer need it.

Final Thoughts

Aluminium profile systems are increasingly replacing steel frames in UK manufacturing environments where flexibility, speed and long-term efficiency are priorities. Their modular design, reduced installation time and adaptability make them well suited to modern production demands. While steel remains essential in certain scenarios, aluminium framing continues to redefine how industrial spaces are built and evolved.